New Research: Decarbonizing the Pulp & Paper Industry

Two new research studies from S. Mostafa Babaei and Prof. Martin K. Patel (University of Geneva) show how heat integration and high-temperature heat pumps (HTHPs) can unlock major efficiency and CO2 reductions in pulp and paper industry:

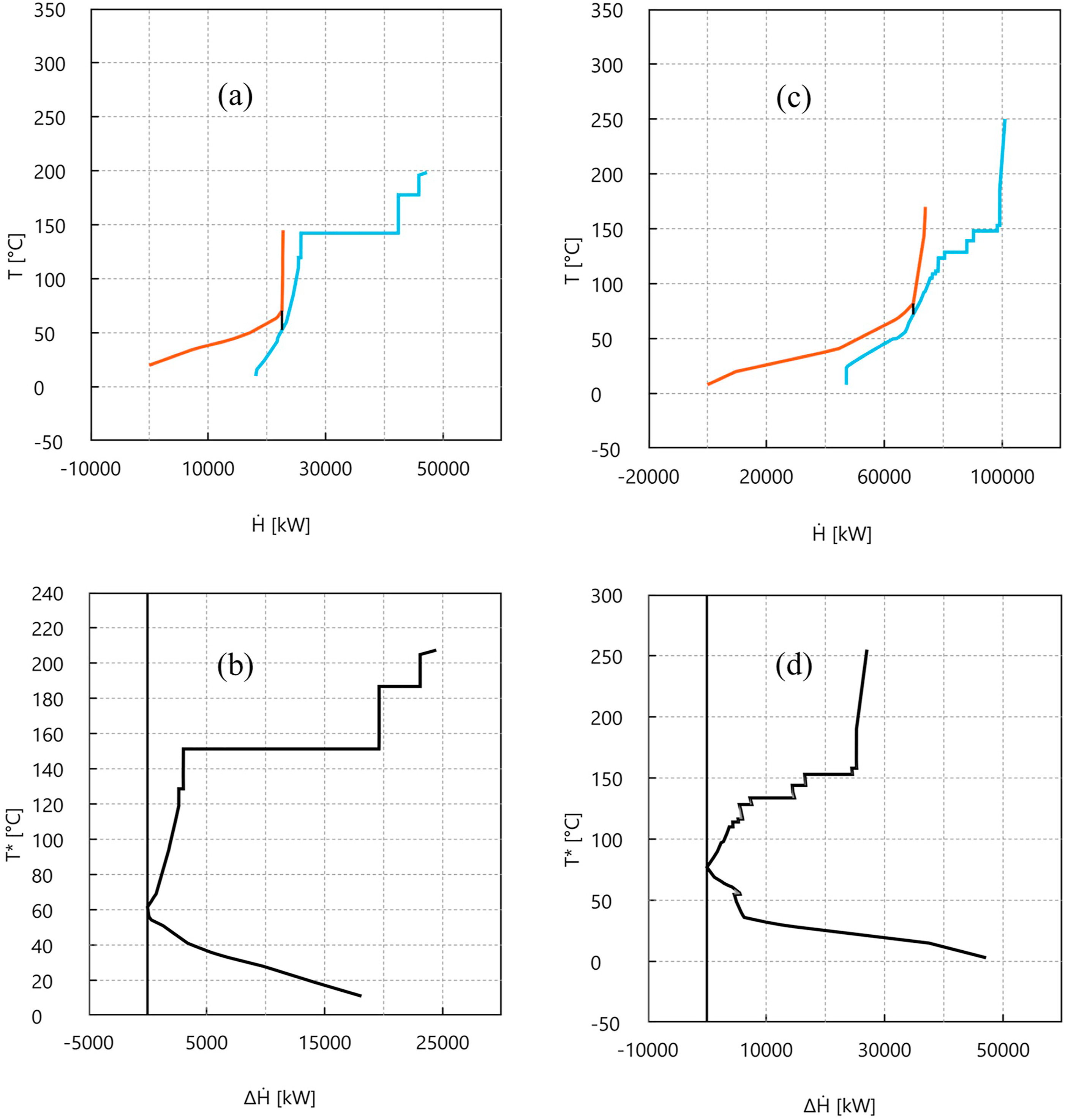

- Advanced heat recovery using pinch analysis significantly reduces energy demand and operating costs

- Techno-economic assessments confirm attractive payback periods, sensitive mainly to energy prices and CAPEX

- Tailored high-temperature heat pumps can replace a large share of fossil-based process heat

- CO2 emissions drop substantially, especially with low-carbon electricity

- Real paper mill case studies prove technical and economic feasibility today

These studies show that combining process integration + innovative heat recovery + HTHPs is a practical pathway toward deep industrial decarbonization of the pulp & paper industry.

Read the full papers here:

- Optimizing energy use in the pulp and paper industry: Pinch, techno-economic, and sensitivity analyses on an innovative heat recovery system, Journal of Cleaner Production, 2025, https://doi.org/10.1016/j.jclepro.2025.146109, This paper combines pinch analysis, techno-economic evaluation, and sensitivity analysis for an innovative heat recovery concept in the pulp and paper industry.

- Deep decarbonization of the pulp and paper industry: Heat integration and techno-economic analysis combined with tailored heat pumps, Energy, https://doi.org/10.1016/j.energy.2025.138881, This work assesses process integration and customized high-temperature heat pumps to reduce fossil fuel use in a real paper mill case study.