In addition to the work carried out in DeCarbCH, HSLU-TEVT has further developed methods and tools using Process Integration. Two examples are described here:

Integration of Heat Pumps and Thermal Energy Storages in Non-Continuous Industrial Processes

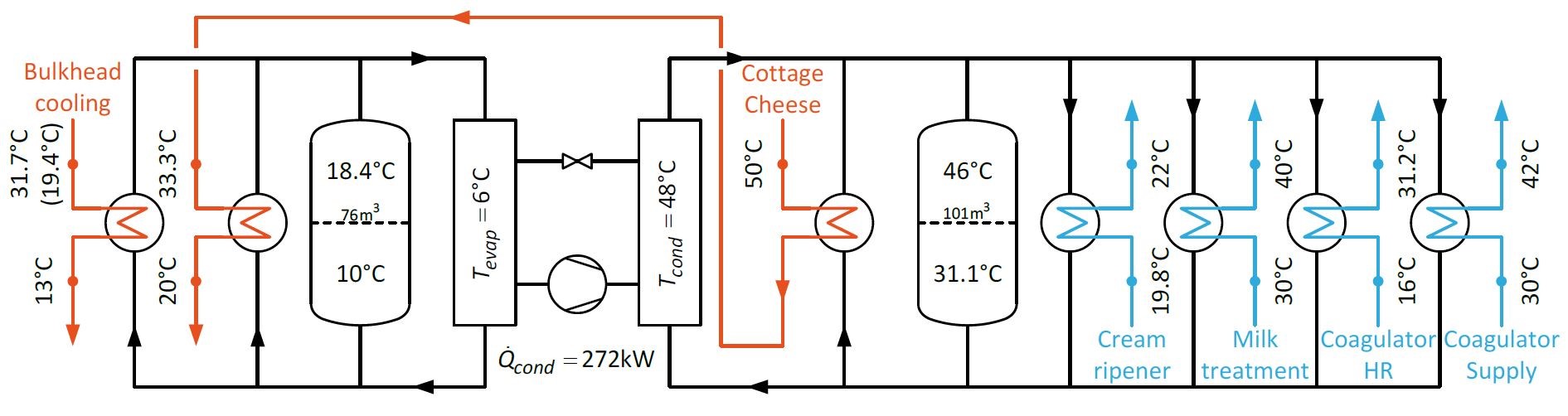

One of the key technologies for decarbonizing the heating and cooling requirements of the industry sector is heat pumps. Due to the high proportion of non-continuous processes in Switzerland, HSLU-TEVT, co-funded by the SFOE, developed a workflow to integrate heat pumps together with thermal energy storage systems to exploit the direct and indirect heat recovery potentials. The workflow consists of existing pinch analysis for direct heat recovery, and the Indirect Source Sink Profile (ISSP) for the indirect heat recovery as well as an extension of the ISSP for the integration of the heat pumps and thermal energy storage systems. The workflow is a variant based approach to the task and is intended keep the practicing engineers in control of the decisions at all stages, allowing and guiding them to decide which solution variants to evaluate.

Literature:

- Agner R., Ong B.H.Y., Stampfli J.A., Krummenacher P., Wellig B., 2022, A Graphical Method for Combined Heat Pump and Indirect Heat Recovery Integration, Energies, 15 (8): 2829. https://doi.org/10.3390/en15082829

Heat exchanger network retrofit for multi-period processes

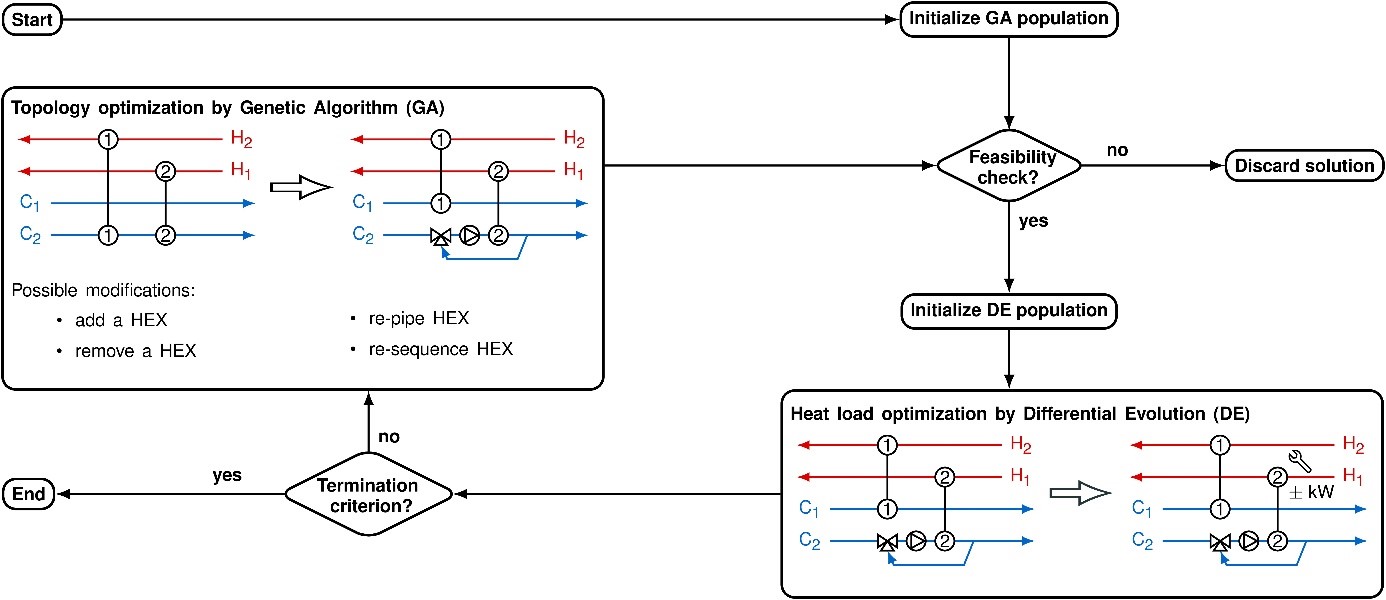

On top of Pinch Analysis methodology, HSLU-TEVT has also been developing further advanced process integration methods, in collaboration with TU-Wien, where the focus lies on transitioning the theoretical approach towards its practical application in the industry. The retrofit of existing plants with multi-period operation is challenging. The periods may experience a high degree of variation (temperatures, mass flow rates, stream existence, etc.). The resulting heat exchanger network needs to be able to ensure feasible heat transfer in each period. Due to the high complexity, the mixed-integer nonlinear programming problem is solved using a hybrid evolutionary algorithm composed of a genetic algorithm optimizing the heat exchanger network topology and a differential evolution optimizing the heat loads for every operating period.

Literature:

- Stampfli J.A., Ong B.H.Y., Olsen D.G., Wellig B., Hofmann R., 2022, Applied heat exchanger network retrofit for multi-period processes in industry: A hybrid evolutionary algorithm, Computers & Chemical Engineering, 161(107771):1-13. https://doi.org/10.1016/j.compchemeng.2022.107771

- Stampfli J.A., Olsen D.G., Wellig B., Hofmann R., 2022, A parallelized hybrid genetic algorithm with differential evolution for heat exchanger network retrofit, MethodsX. https://doi.org/10.1016/j.mex.2022.101711