Question: Could you describe the topic of your WP?

Answer Prof. Beat Wellig: Work Package 4 deals with the identification of energy demand profiles of Swiss industrial companies using existing Pinch Analysis, as well as the development of practical tools and methods to guide users in industry in obtaining their own profiles. These energy demand profiles will transparently show how companies can increase their energy efficiency, integrate renewables into their heating and cooling systems optimally, as well as identify both their potential for excess heat utilization and the inclusion of negative emissions technologies into their processes. The work will also address the efficient cold generation, the cooling potential by using locally available free cooling, and feeding excess heat to thermal grids and buildings, and integrating recooling heat into processes and infrastructure.

Question: What are the main objectives?

B. Wellig: In industry, there is a need for analysis and design methods based on a holistic view. The systematic overall optimization of processes and energy systems is called Process Integration, whereby the best-known tool is Pinch Analysis. Pinch Analysis allows to establish the minimum heating and cooling requirements for the case of maximum heat recovery of a system. It is also possible to determine how this condition can be achieved economically with the implementation of energy efficiency measures (EEMs). Further, the holistic and systematic approach of Process Integration is a prerequisite for the proper integration of renewables.

The main objective of WP04 is to enhance the understanding of the energy demand profiles (quantity, quality, temporal) of industrial processes to facilitate successful integration of renewables. The Work Package is developing tools to drive and broaden the application of important Process Integration techniques such as Pinch Analysis, which continue to play a crucial role in decarbonizing industry, for both larger companies and SMEs.

Question: How does it relate to DeCarbCH?

B. Wellig: Heating and cooling in industry is responsible for approximately 42% of the CO2 emission of the total heating and cooling in industry and residential. One of the objectives of DeCarbCH is to develop solutions by identifying suitable renewables and properly integrating them into the industrial processes based on an understanding of the limitations of renewables due to availability, temporal constraints, etc. Industry has very specific, widely varying requirements regarding the energy demand profiles. WP04 will develop tools and methods to drive and promote simple and cost-effective Pinch Analysis in industry. Such systematic and holistic analyses are a fundamental starting point for correct integration of renewables for process heating and cooling and energy efficiency measures in general.

Question: What are the main expected outcomes of your WP?

B. Wellig: One of the outcomes is the thorough understanding of the current and future demands of industrial heat. Currently, there are only rather rough estimates for the share of heat in the low, medium and high temperature range. These estimates relate to EU-wide estimates, which may not be representative for the Swiss situation, which is less dominated by heavy industry with high temperature heat demand.

The other key outcomes are the construction of exemplary energy profiles and sectorial energy profiles. The exemplary energy profiles represent the energetic demands and excess heat at company level for various production classes in Switzerland. This is important to help industry to identify their potential to improve their energy efficiency and allow practitioners to scale the exemplar energy profile according to their production size and to explore their potential renewables integration opportunities. The sectorial profiles on the other hand, aid the understanding of the energetic demands of the various industry sectors.

Question: Could you provide some examples?

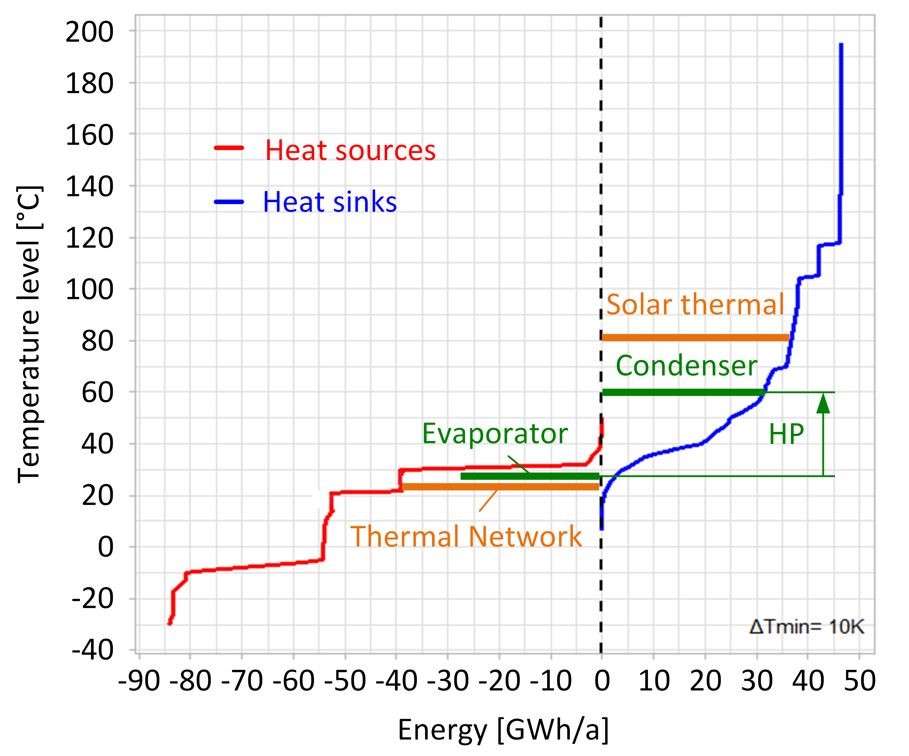

B. Wellig: To identify company potential to integrate renewables as well as the external use of excess heat, Composite Curves (CCs) and Grand Composite Curves (GCCs) are essential. Through these curves, practitioners can identify the potential for direct heat recovery, heat pump integration, utility systems optimization, etc. Tools and methods for rendering meaningful CCs and GCCs of individual complex production processes, as well as complete industrial companies including infrastructure and their environment, are currently being developed; allowing engineers and planners to obtain profiles.

Based on the GCCs of individual companies from a specific (sub-)sector, sectorial energy demand profiles will be created. The source/sink profile of the “meat” subsector is shown below as an example. Different opportunities can be identified and quantified using these profiles, for example, a huge heat pumping potential exists within the subsector. As an alternative, a large portion of the heating demand can be covered by solar energy or the excess heat can be supplied to low-temperature thermal grids.

Question: A final word for our readers?

B. Wellig: With the aim of achieving net zero emissions, determining industrial energy demand profiles, based on real data using Process Integration techniques, is a crucial precursor. Process Integration supports the integration of renewable heating and cooling, and excess heat use (e.g. in thermal grids), as they form the basis for accurate characterization and eventual matching of demands with suitable renewables technologies emerging and currently on the market.