Date: 21 August 2025

View the full article by Sung Yujin in Korean, E-mail: yjsung@kharn.kr

Translated from Korean to English (Cordin Arpagaus, OST).

World ENC hosted an international joint Swiss–Korean research workshop to share the progress of the R&D project Development and Demonstration of a Steam Production System Using Waste Heat–Driven Absorption Heat Transformer and MVR in Industrial Processes.

World ENC, the organizer of the workshop, is a technology-driven company specializing in the development of advanced refrigeration and chiller systems. The company is currently expanding its portfolio with the development of its own oil-free turbo chiller and screw chiller, building on a foundation of 25 registered patents.

World ENC offers 19 models of oil-free turbo chillers, ranging from 80 RT to 600 RT class (280 kW to 2'110 kW), as well as modular-type oil-free chillers with capacities between 80 RT and 140 RT (280 kW to 490 kW).

In addition, the company has developed its own control system and user interface. The system is based on a PLC controller, capable of operating seamlessly with two to three compressors.

World ENC’s products have been successfully installed in a variety of locations, including the Sejong Government Complex, Incheon International Airport, chemical plants, hospitals, and commercial facilities such as Homeplus and Gwangmyeong Lotte Outlet, where they have demonstrated strong reliability and performance.

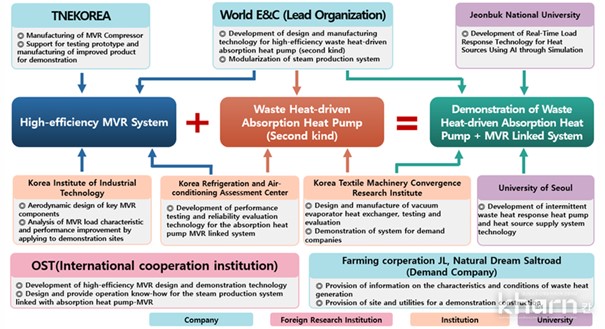

The role of each consortium partner

The co-implementing organizations of this project, with World ENC serving as the host organization, are: TNE Korea, the Korean Institute of Industrial Technology (KITECH), the Refrigeration and Air Conditioning Testing and Research Institute (K-HVAC), the Korea Textile and Machinery Convergence Research Institute (KOTMI), Chonbuk National University, the University of Seoul, and OST.

The initiative is being conducted as a demonstration project for Natural Dream Salt Road and Ominara.

-

World ENC, as the organizer, will develop an absorption heat transformer and establish a demonstration site during the 3rd and 4th project years.

-

TNE Korea will be responsible for MVR (Mechanical Vapor Recompression) design, manufacturing, and testing.

-

KITECH will lead the aerodynamic design.

-

K-HVAC will build performance testing equipment and establish standardized test methods for absorption heat pumps and MVR systems.

-

KOTMI will develop a vacuum evaporative heat exchanger and install it at the demonstration site in the 3rd–4th years.

-

Chonbuk National University will design the absorption heat pump cycle and absorption heat pump–MVR system, as well as develop AI-based control technology.

-

University of Seoul will focus on heat storage, heat source analysis, and heat storage system technology.

-

OST Eastern Switzerland University of Applied Sciences is an international cooperation partner that supports providing knowledge about steam generation.

In his opening remarks, Kim In-gwan, Director of World ENC, stated:

“We have completed the first year and entered the second year with the tasks carried out by nine organizations. Through this workshop, we will provide a place to discuss the technical aspects in depth.”

In his welcome speech, Lee Kwang-hoon, Senior Vice President of the Korean Society of Mechanical Engineers, remarked:

“Congratulations on holding a joint workshop on the theme of heat pumps and MVR technology for industrial process steam production. Korea and Switzerland are countries that have led technological innovation for sustainable industrial development and carbon neutrality. This workshop will be an important turning point in bringing together the research capabilities of both countries to advance the spread of heat pump and MVR technology.”

He added:

“I hope this initiative will go beyond academic exchanges and lead to practical applications. I also hope it will make a significant contribution to improving energy efficiency and building a sustainable future through demonstration.”

Absorption heat transformer (AHT) and MVR technology

🔑 Project Goals

-

Produce high-temperature steam (160 °C) by combining Absorption Heat Transformer (AHT) (raises low-grade waste heat < 90 °C to 120 °C steam/hot water) and Mechanical vapor recompression (MVR) (recompresses 120 °C steam up to 160 °C)

-

Expected benefit: ~80% reduction in energy use compared to conventional steam boilers

⚙️ Technology Flow

-

Absorption Heat Transformer

-

Waste heat supplied to evaporator & regenerator

-

Produces 120 °C hot water

Condensed refrigerant (~37–38 °C) will first pass through a heat exchanger before the evaporator -

Target COP: 0.45

-

-

Steam Handling

-

120 °C steam → superheater → compressor → cooled → 160 °C steam for industrial use.

-

Uses a two-stage compression system.

-

Flash tank with demister prevents mist carryover.

-

-

MVR (Mechanical Vapor Recompression)

-

Boosts steam temperature and pressure

-

High-efficiency design improvements are a major R&D task

-

Potential fallback: apply MVR alone if AHT integration is difficult

-

📍 Demonstration Sites

-

Natural Dream (deep water heat exchanger)

-

Steam boiler produces 120 to 130 °C steam for distillation

-

Waste heat at 90 to 95 °C currently discarded

-

Plan: recover and reuse this waste heat via AHP + MVR

-

-

Ominara distillation process

-

Uses 120 to 130 °C steam.

-

Capture 90 to 95 °C waste heat.

-

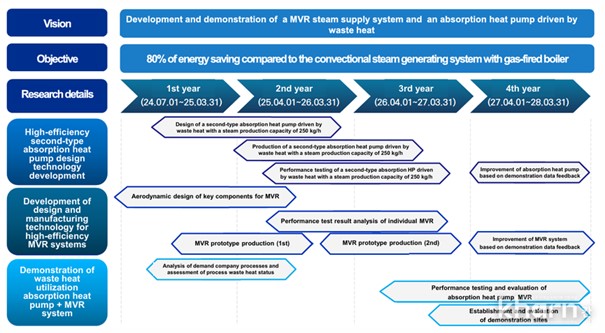

🏗️ R&D Roadmap

-

Year 1–2 (current phase):

-

Develop Absorption Heat Transformer (AHT) and MVR technologies

-

Carry out system design (i.e., flash tank, heat exchangers, cycle optimization)

-

-

Year 3:

-

Build demonstration sites with AHP + MVR linkage.

-

Verify operation in real industrial processes.

-

📊 Business Model & Commercialization

-

Focus sectors: food, paper, textile, chemical, power, energy industries (major CO₂ emitters)

-

Target customers: small, medium, and large companies

-

Activities:

-

Risk & economic feasibility analysis

-

Discover applicable processes

-

Recruit early customers

-

Tailor enhancement plans for each industry

-

✅ In short: The project is developing an integrated waste-heat recovery system using AHT and MVR, aiming for 160 °C process steam with drastic energy savings, industrial CO₂ reduction, and broad cross-sector applicability.

Aerodynamic design of the compressor for MVR

Dr. Choi Young-seok of KITECH (Korea Institute of Industrial Technology) presented progress on the aerodynamic design of the compressor.

Due to numerous design constraints, careful consideration is required to determine the optimal compression ratio.

The target operating range is 160 °C, with a condensation pressure of 635.8 kPa corresponding to 287.5 °C. Based on these conditions, the compressor’s size, width, and inlet diameter are being designed.

Dr. Choi explained: “We carried out aerodynamic design to achieve the required compressor performance under these conditions. The system uses two-stage compression, and simulations of pressure and efficiency indicated a required power of 26.5 kW. These results provided the basis for setting design standards.”

To further enhance performance, the research team has implemented design modifications, including adjustments to the splitter position to improve efficiency and optimize airflow.

Looking ahead, Dr. Choi noted: “We expect to begin testing in the third year and will address any issues that arise during prototype manufacturing.”

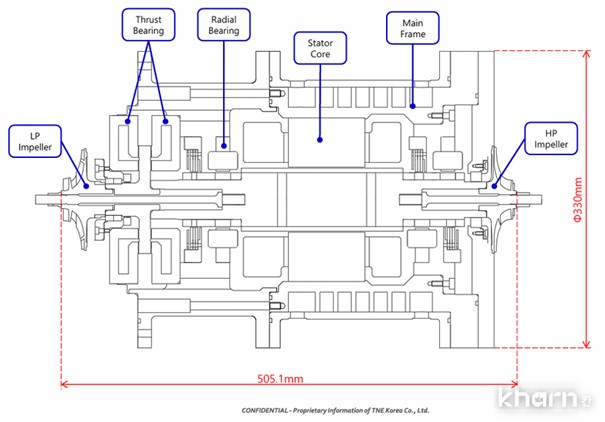

MVR Mechanical Design and Analysis

Kim Kyung-so, Vice President of TNE Korea, outlined the company’s role in the project, focusing on motor design.

The motor is being developed to deliver 70,000 RPM and 60 kW, meeting the power requirements of the generator.

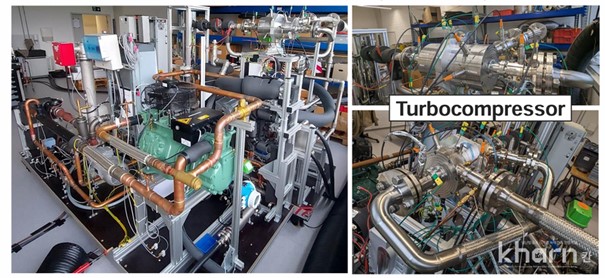

An oil-free, non-contact system using magnetic bearings is applied, enabling electronic control. The MVR design integrates high-speed motors, magnetic bearings, and cooling considerations.

Vice President Kim explained: “The motor has a compact form factor, with a length of 505 mm (impeller end) and a diameter of 330 mm.”

Structural integrity was verified under high-speed operation, confirming no abnormalities despite the large impeller load. For material optimization, the first stage is designed in aluminum and the second stage in titanium. Cooling will maintain the motor at ≤180 °C and the magnetic bearings at ≤150 °C.

Looking ahead, Kim stated: “We aim to finalize the design analysis and detailed component design soon, with the first prototype completed within this year. Next year, we plan to begin production of the second prototype and initiate delivery, adjusting the schedule based on first-prototype test results.”

Industrial heat pump trends and MVR test facility development

Dr. Kim Cheon-cheon (K-HVAC) shared recent trends in industrial heat pumps.

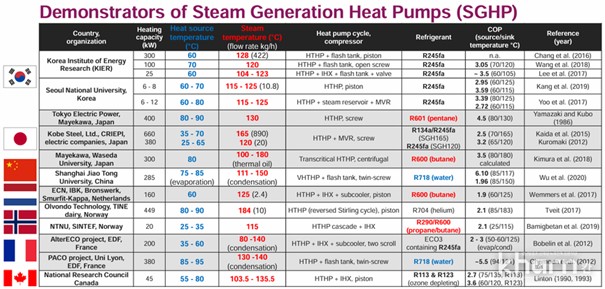

Research is focusing on replacing energy-intensive steam boilers. Absorption Heat Transformers use 60 to 95 °C heat sources to produce 100 to 150 °C steam.

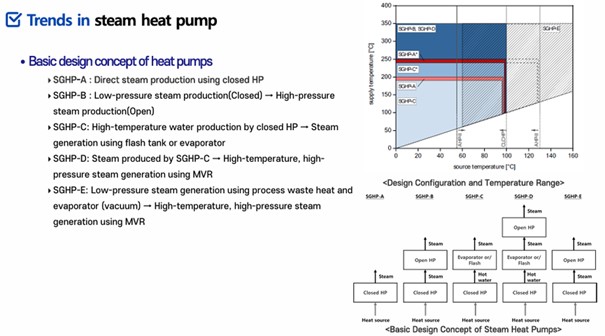

Heat pump designs can be classified into five categories with different supply temperatures. Class A uses compressed heat pumps for steam production, while Class D combines absorption and compression with flash tanks and MVR to generate high-pressure steam.

MVR development is led by Japan and Europe. In Korea, steam heat pump R&D began in the mid-2010s (300 kW, 120 to 165 °C) and by 2023 scaled up to systems above 3 MW.

Recent efforts target scaling heat pump capacity up to 1'000 RT (3'517 kW). For MVR, short-term work focuses on core component development, while the medium-term goal is a 3 MW turbo heat pump applicable to MVR. The priority is to move these technologies into real-world demonstration.

K-HVAC is working on the development of standard performance evaluation methods, supporting the next generation of large-capacity heat pumps.

As part of this initiative, the company is building dedicated test facilities for mechanical vapor recompression (MVR) and absorption heat pumps, and has drafted an initial design concept.

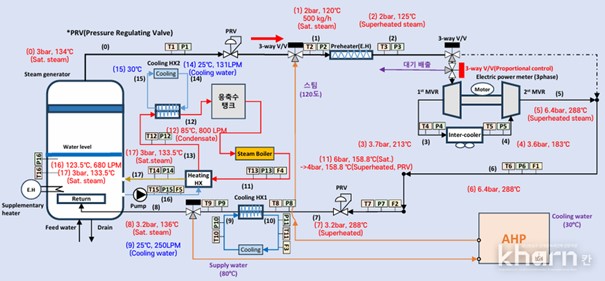

In the planned test cycle, steam will be generated by supplying heat sources via a condensing tank and steam boiler. After preheating, the steam will undergo two-stage compression in the MVR system, producing steam at 288 °C and 6.4 bar. This high-pressure steam will be recycled within a closed cycle, eliminating waste.

Dr. Kim Cheon-cheon emphasized: “We plan to integrate the system with our additionally developed absorption heat transformer and actively contribute to demonstration projects in cooperation with Saengyeon, TNE Korea, and World ENC.”

Introduction to OST and high-temperature heat pump technology trends

Prof. Daniel Gstoehl and Dr. Cordin Arpagaus from OST Eastern Switzerland University of Applied Sciences ipresented their research results on high-temperature heat pumps.

OST is a university of applied sciences with approximately 4'000 students and hosts a dedicated heat pump test center within its Institute for Energy Systems (IES). The institute employs around 30 researchers and is actively engaged in projects on heating and cooling systems, industrial heat pumps, thermal energy storage, and energy efficiency, with recent collaborations including partners in South Korea.

Established in 1993, the heat pump test center has the capacity to test up to 100 heat pumps per year. It is equipped for both steam and high-temperature testing, handling temperatures of up to 200 °C.

High-Temperature Heat Pumps: A Promising Technology for Decarbonization

High-temperature heat pumps are increasingly recognized as a key technology for reducing dependence on fossil fuels and enabling the efficient use of renewable electricity. The commercialization of industrial heat pumps with operating temperatures in the 100 to 250 °C range is already underway in regions such as Europe, Japan, Germany, and Austria, with capacities expanding from a few hundred kilowatts to large-scale systems up to 10 MW.

Recent innovations, including oil-free high-speed turbocompressors, multi-stage compression methods, and the use of natural refrigerants, have improved both performance and market potential.

Dr. Cordin Arpagaus from OST emphasized: “The choice of refrigerant is critical in heat pump development. While synthetic refrigerants (e.g., R245fa) are often used today in Korea, alternatives are explored such as ammonia, CO₂, or helium to reduce the global warming potential (GWP).”

The cost of heat pumps depends on several factors, including the refrigerant type, temperature range, and cycle design, leading to substantial variations in economic feasibility depending on local electricity and gas price structures. For instance, in Northern Europe, where electricity and gas prices are relatively balanced, heat pump adoption is highly advantageous. In contrast, in regions like the UK, where electricity prices are comparatively high, the economic benefits are less pronounced.

High-Temperature Heat Pump Projects Across Europe

Numerous industrial heat pump projects are currently underway in Europe. For example:

-

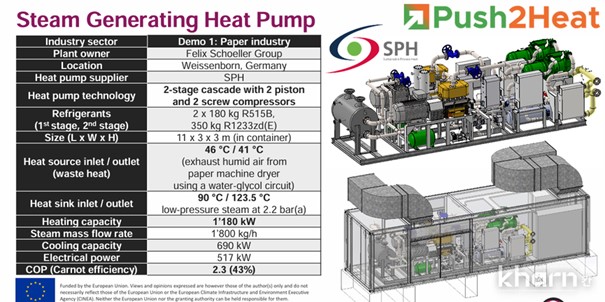

Spirit is developing heat pumps to sugar and paper mills.

-

Push2Heat is implementing two-stage compression heat pumps in paper and chemical factories.

Dr. Cordin Arpagaus from OST noted: Recently, a 6-cylinder Stirling-cycle heat pump has been developed in Norway and is being commercialized in capacities ranging from 100 kW to 1 MW.”

In Norway, Aneo is developing heat pumps capable of handling high temperatures above 90 to 95 °C using ammonia-water mixed refrigerants, along with turbos, pistons, and screw compressors.

At OST, research on small-scale heat pumps began in 2017, achieving results through the use of natural refrigerant mixtures (e.g., HFOs, hydrocarbons), vapor compression, and MVR technology. The institute is also actively investigating optimal cycle design, producing excellent experimental results.

Dr. Arpagaus emphasized: “Energy prices and policy environments vary from country to country, but industrial heat pumps are a common solution for decarbonization worldwide. I look forward to contributing to collaboration with Korea through the experience and research results from Switzerland and other European countries.”